define diamond-pyramid hardness test|diamond pyramid hardness testing : purchase Hardness testing measures a material’s resistance to permanent deformation at its surface, by pressing a harder material into it. It is used in a number of industries for material comparison and selection, as well . Localizado em Santa Cruz da Serra, no Parque Equitativa, O Sítio Enfesta e o Chalé Enfesta está preparada para quem quer viver um momento de alegria, felicidade e .

{plog:ftitle_list}

Francisco António Machado Mota de Castro Trincão ( European Portuguese: [fɾɐ̃ˈsiʃku tɾĩˈkɐ̃w̃]; born 29 December 1999) is a Portuguese professional footballer who plays as a .

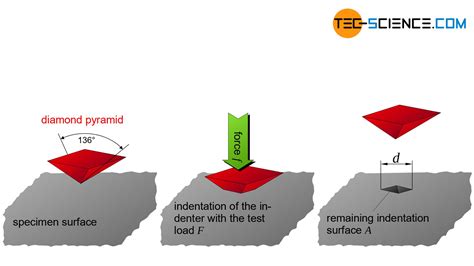

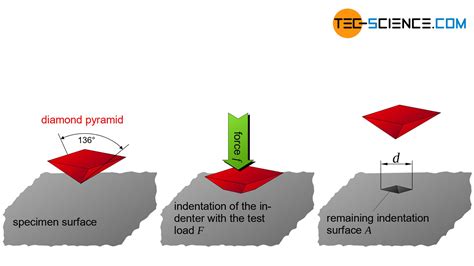

The Vickers hardness test or the 136 degree diamond pyramid hardness test is a microindentation method. The indenter produces a square indentation, the diagonals of .Vickers hardness is also sometimes called Diamond Pyramid Hardness (DPH) owing to the shape of the indenter. Test samples should have a smooth surface and be held perpendicular to the indenter. All things being equal, a lighter .

This is called as the Vickers Pyramid Number (HV) or the Diamond Pyramid Hardness (DPH). These units are convertible to pascals but should not, in any form, be used interchangeably with the same unit that .Definition. The Vickers hardness test is a method used to measure the hardness of materials, specifically metals, by indenting the material with a diamond pyramid under a specific load. Hardness testing measures a material’s resistance to permanent deformation at its surface, by pressing a harder material into it. It is used in a number of industries for material comparison and selection, as well .

Vickers hardness, a measure of the hardness of a material, calculated from the size of an impression produced under load by a pyramid-shaped diamond indenter. Devised in the 1920s by engineers at Vickers, Ltd., in the United .Vickers Hardness Testing Formulas, Calculator and Review. The Vickers test can be used for all metals and has one of the widest scales among hardness tests. The unit of hardness given by the test is known as the Vickers .

The Vickers test can be used for all metals and is one of the widely used test among hardness tests. The unit of hardness is known as the VICKERS PYRAMID NUMBER (HV) or DIAMOND PYRAMID HARDNESS (DPH).

The Vickers hardness test was developed by George E. Sandland and Robert L. Smith at Vickers Ltd. in the year 1921, as an alternative to the Brinell method to determine the hardness of materials. This Vickers hardness test is usually . As with every other hardness test, the Vickers procedure uses its own unit of hardness. This is called as the Vickers Pyramid Number (HV) or the Diamond Pyramid Hardness (DPH). These units are convertible to pascals .The Vickers hardness tester uses a square-based diamond pyramid indenter, and the hardness number is equal to the load divided by the product of the lengths of the diagonals of the square impression. Vickers hardness is the most accurate for very hard materials and can be used on thin sheets.

The Vickers hardness test is a method used to measure the hardness of materials, specifically metals, by indenting the material with a diamond pyramid under a specific load. This test provides a hardness value that correlates with the material's resistance to deformation and wear, linking it to surface hardness and elasticity, which are critical properties in engineering .

Hardness testing is a vital process in many industries. Our guide explains everything you need to know about this crucial technique. . Vickers hardness 1. Principle. Press a diamond pyramid into the metal surface with a certain load F to form a pyramid indentation. . the traditional definition of hardness will yield an infinite value .Angles of a Knoop hardness test indenter. The Knoop hardness test / k ə ˈ n uː p / is a microhardness test – a test for mechanical hardness used particularly for very brittle materials or thin sheets, where only a small indentation may be made for testing purposes. A pyramidal diamond point is pressed into the polished surface of the test material with a known (often . Hardness testing is a mechanical test that measures a material's resistance to indentation, scratching, or abrasion. . This test measures the size of an indentation made on the surface of the material by a diamond pyramid under a specific load. This test is commonly used for thin materials or coatings. . Definition, Usage, and Context 2024 .An indentation hardness test in which a diamond-pyramid indenter, with a 136° angle between opposite faces, is forced under variable loads into the surface of a test specimen.

Get all your information on Vickers hardness testing to ISO 6507 from ZwickRoell Definition Advantages and disadvantages Examples More information. . The indenter used in the Vickers test method is a diamond pyramid with a square base, whose opposite sides meet at the apex at an angle of α = 136°. It is applied to the specimen with a test .

For the Vickers hardness test, a square base pyramid with a opening angle of 136° is used as the indenter (opening angle = angle between two opposite surfaces of the pyramid). The angle was chosen so that the Vickers hardness values are comparable to a certain degree with the Brinell hardness values (applies to approx. 400 HBW or 400 HV). The .Indentation hardness value is obtained by measuring the depth or the area of the indentation using one of over 12 different test methods. Learn more about hardness testing basics here. The Rockwell hardness test method, as defined in ASTM E-18, is the most commonly used hardness test method. You should obtain a copy of this standard, read and .What is Hardness – Definition. In materials science, hardness is the ability to withstand surface indentation (localized plastic deformation) and scratching. . A square base pyramid shaped diamond is used for testing in the Vickers scale. For microindentation typical loads are very light, ranging from 10gf to 1kgf, although macroindentation .

Specimens randomly selected and submitted to a Vickers hardness test with a diamond pyramid head of a Duramin-1 Vickers hardness tester (Struers) under a predetermined load (9.807 N) over 15 s to induce a diamond-shaped indent. The size of each diagonal distance was measured and the Vickers hardness was calculated according to the surface area .

Indentation hardness value is obtained by measuring the depth or the area of the indentation using one of over 12 different test methods. Hardness Testing Considerations The following sample characteristics should be considered prior to selecting the hardness testing method to use: • Sample Size • Cylindrical Samples • Sample Thickness

Brinell Hardness Test: Rockwell Hardness Test: In Brinell Hardness Test the indenter is a spherical Tungsten Carbide Ball: For the Rockwell Hardness Test, the Indenter is a Small Steel Ball (HRB) or a diamond cone (HRC) Hardness .The Vickers hardness test uses a square-base diamond pyramid as the indenter. The included angle between opposite faces of the pyramid is 136°. This angle was chosen because it approximates the most desirable ratio of indentation diameter to ball .The Rockwell hardness test uses both a diamond cone (for the hardest materials) and various sizes of steel balls for medium to hard materials. The two most commonly used in testing welds are Rockwell C and the Rockwell B. .

Two common indenters for this method are the Vickers diamond pyramid or the Knoop elongated diamond pyramid. The testing process mirrors the standard Vickers hardness test, but it's executed on a much smaller scale and demands more precision equipment. For the test to be effective, the target surface typically needs a metallographic polish.Units of Hardness – Hardness Numbers – Definition. Units of hardness. There are a variety of hardness test methods in common use (e.g. Brinell, Knoop, Vickers and Rockwell). . A square base pyramid shaped diamond is used for testing in the Vickers scale. For microindentation typical loads are very light, ranging from 10gf to 1kgf . Knoop Hardness Test. The Knoop hardness test, which assesses a material's resistance to indentation by a pyramid-shaped diamond tip with a known force and dwell time, is a microhardness test. The Knoop hardness test is particularly appropriate when only a little indentation can be formed to evaluate brittle materials or thin sheets.

The Vickers Test is a method for measuring the hardness of materials, using a diamond pyramid indenter to create an impression on the material's surface. This test is significant in material testing and characterization as it provides valuable insights into a material's mechanical properties, allowing for comparisons between different materials and informing decisions about .See also: Hardness. Rockwell Hardness Test. Rockwell hardness test is one of the most common indentation hardness tests, that has been developed for hardness testing. In contrast to Brinell test, the Rockwell tester measures the depth of penetration of an indenter under a large load (major load) compared to the penetration made by a preload .The Vickers hardness test method, also referred to as a microhardness test method, is mostly used for small parts, thin sections, . A square base pyramid shaped diamond is used for testing in the Vickers scale. Typically loads are very light, ranging from 10gm to 1kgf, although "Macro" Vickers loads can range up to 30 kg or more. .

what is diamond pyramid hardness

The Vickers test utilizes its unit of hardness, known as the Diamond Pyramid Hardness (HV) or Vickers Pyramid Number (DPH). Unlike pressure units, HV should not be used as a substitute. The test involves applying a load onto a specially designed diamond indenter, creating an indentation on the material’s surface.

The Vickers hardness testers with square-based pyramid indenter tip or Knoop hardness testers with pyramid indenter tip are the most traditional and common methods of measuring the hardness of materials, where the indenter tip made of natural single crystal diamond (N-D) makes an indent on the well-polished surface of test material under a .Brinell Hardness The Vickers hardness test utilizes a pyramidal diamond in-denter to create an indentation on the material‘s surface. The diagonals (x and y axis) of the indentation are measured, and the hardness value is calculated based on the applied load and the indentation size. Vickers belongs to the optical methods. Vickers HardnessThe Vickers hardness test is often regarded as easier to use than other hardness tests: The process can be performed on a universal or micro hardness tester; the required calculations are independent of the size of the indenter; and the same indenter (a pyramidal diamond) can be used for all materials, irrespective of hardness.

3-point bending test

3-point bending test pdf

2 de jan. de 2024 · How to get free Robux? 1. Get 1,700 free Robux by helping your parents save money; 2. Free Robux generators: Are they scams? Free Robux: Other .

define diamond-pyramid hardness test|diamond pyramid hardness testing